Our mixers have always been designed to keep plants and workers safe, preform reliably and stay tough. When designing our first mixer, A.C. addressed specific application challenges that he had experienced while working in the petroleum industry—a major factor being worker safety in keeping the workers out of the tanks themselves as much as possible. He pioneered our vari-angle (i.e. swivel) design and pitch-adjusted propellers that have set Jensen apart from the competition for OVER 70 YEARS. As our mixers have evolved, we have incorporated key features such as Petro-Block, the Phoenix Propeller, Sentry Notification System and First Watch Notification System. These features are not only built to last and easy to maintain, but are also the most advanced mixers on the market to this day.

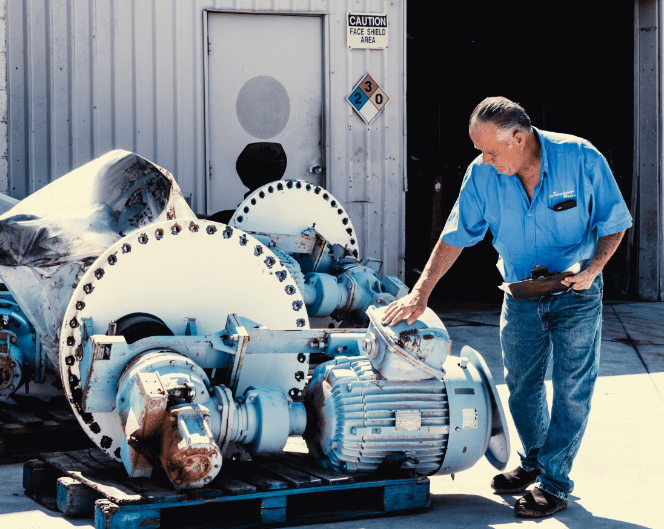

Whether you need a complete mixer remanufacture, a gearbox repaired, a new mechanical seal or an actuator, Jensen has you covered. We’re proud to offer remanufacturing and repair services on all of our mixer models and various components. Simply ship us your used equipment and our technicians will perform a complete remanufacturing and discuss options to update equipment to match today’s design. Contact our factory or your local representative for more details.

Complete mixer install? Replacing a gearbox? Exchanging a Mechanical Seal? Jensen is here to help. With On-Site guidance, our trained technician can visit your site for a one-on-one course or to work with your team on addressing common maintenance procedures. Contact us today to schedule training or maintenance assistance.

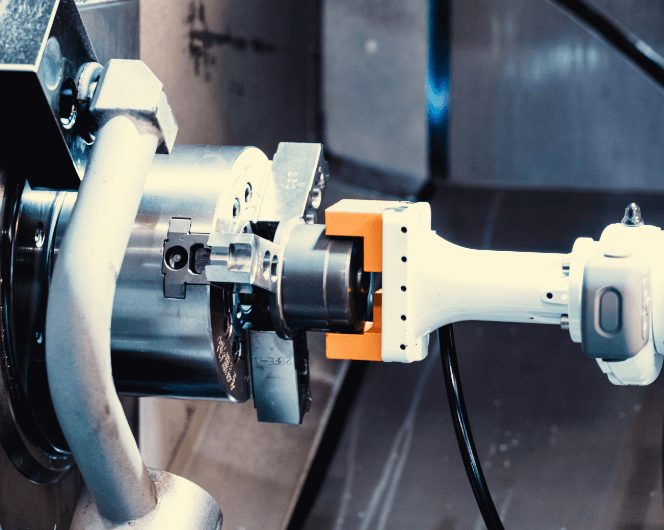

Requiring only seconds to activate, Jensen’s new safety feature, the Petro-Block, is 99% effective in keeping the product where it belongs … in the tank!

Sentry Notification System buys you time before leaks spill on the ground.

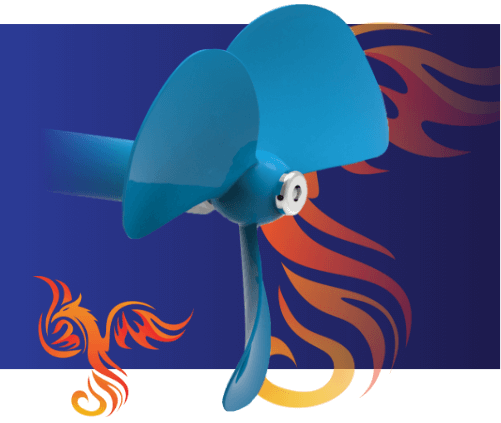

Each Phoenix Propeller is created to match a specific application’s pitch-to-diameter ratio to maximize performance.

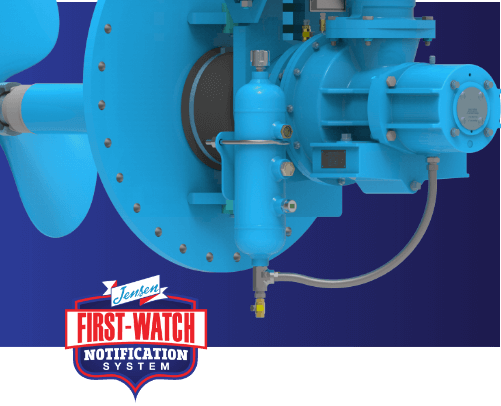

Jensen’s First-Watch system is gives you time to react when a mixer seal needs attention.

Jensen made the lock-off procedure even easier with the introduction of the Draw-Lock.

When it comes to proper management of BS&W, crude oil blending and storage tank cleaning, side-entry mixers are a must. As a tank-mixer supplier founded in conjunction with the petroleum industry, Jensen Mixers has become one of the leading providers of heavy-duty side-entry agitators. Side entry agitators and commonly referred to as the Most Respected Mixer Manufacturer in the World.

Whether you are blending, lubricants, additives, crude oil, biofuels or bitumen, you likely need to reduce the amount of settling occurring to achieve your desired finished product. Side-entry mixers can also be utilized to maintain consistent temperatures throughout storage tanks for products that require high-temperature ranges.

Jensen Mixers International, Inc.

P.O. Box 470368

Tulsa, OK 74147

Jensen Mixers International, Inc.

5354 S. Garnett Rd

Tulsa, OK 74146

© 2025 Jensen Mixers | Website by Byers Creative